Waste Management

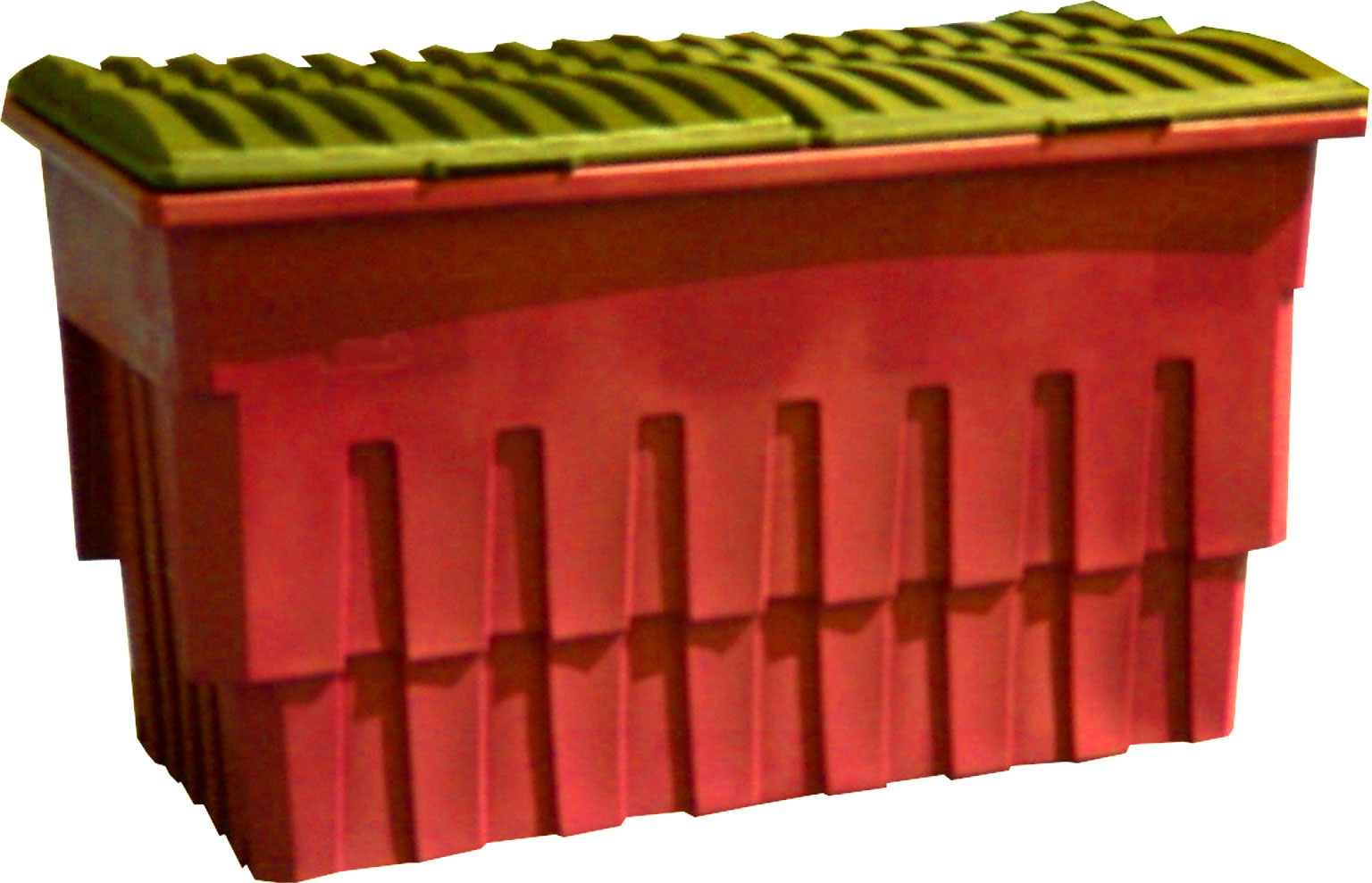

Granger Plastics manufactures a wide variety of products for the Waste Management and Recycling industries. There are a number of containers available for waste management purposes, or custom design and manufacturing services are also available to meet specific waste management needs. Granger Plastics molds products for commercial entities, cities and municipalities, recycling facilities and metal scrapping facilities. Whether a high end, revenue generating advertising trash can or a cubic yard dumpster, Granger has the capabilities to exceed your expectations!

Granger Plastics molds thousands of different custom rotationally molded solutions for many industry leaders. Granger Plastics is an integral solution provider for a broad range of companies including waste management options for many applications. Granger Plastics possesses capabilities that are a far stretch to the common rotational molder. Not just the ability to mold in complex inserts, threaded fittings, foam filling or molding heavy wall intricate parts, but Granger Plastics can also assist in the design and development of your complete waste management solution. Having the ability to mold intricate plastic components, build molds, assemble, package, design and engineer solutions all under one roof! The Granger Plastics Company is your partner in rotational molding!

Waste Management Gallery

|