Plastic Pallets

Pallets are a material handling structure that supports goods and products in a stable fashion while being moved by forklift, pallet jack, front loader, work saver or other material handling device. Often erronesouly called 'skids', pallets are different by having bottom deck boards, where as skids do not.

Plastic Pallets offer a number of distinct advantages over wooden and metal skids. A number of industries including food, pharmaceutical, chemical, printing and medical facilities are all rapidly converting from wood or metal to plastic pallets for use. Improved hygiene, cleaning and sanitization are immediate features that are features found in plastic pallets that are not available from cheap, disposable wooden pallets. Plastic Pallets also provide an elimination of messy wood splinters, wood chips, nails and more, thus keeping your work areas cleaner and safer.

Plastic Pallets also offer improved, longer usable service life and lighter repeatable tare weights with dimensional consistency in comparison to less durable wooden pallets. Typically, these longer service lifespans coupled with safer, more efficient work environments provide an overall savings and improvement in efficiencies where other units fail.

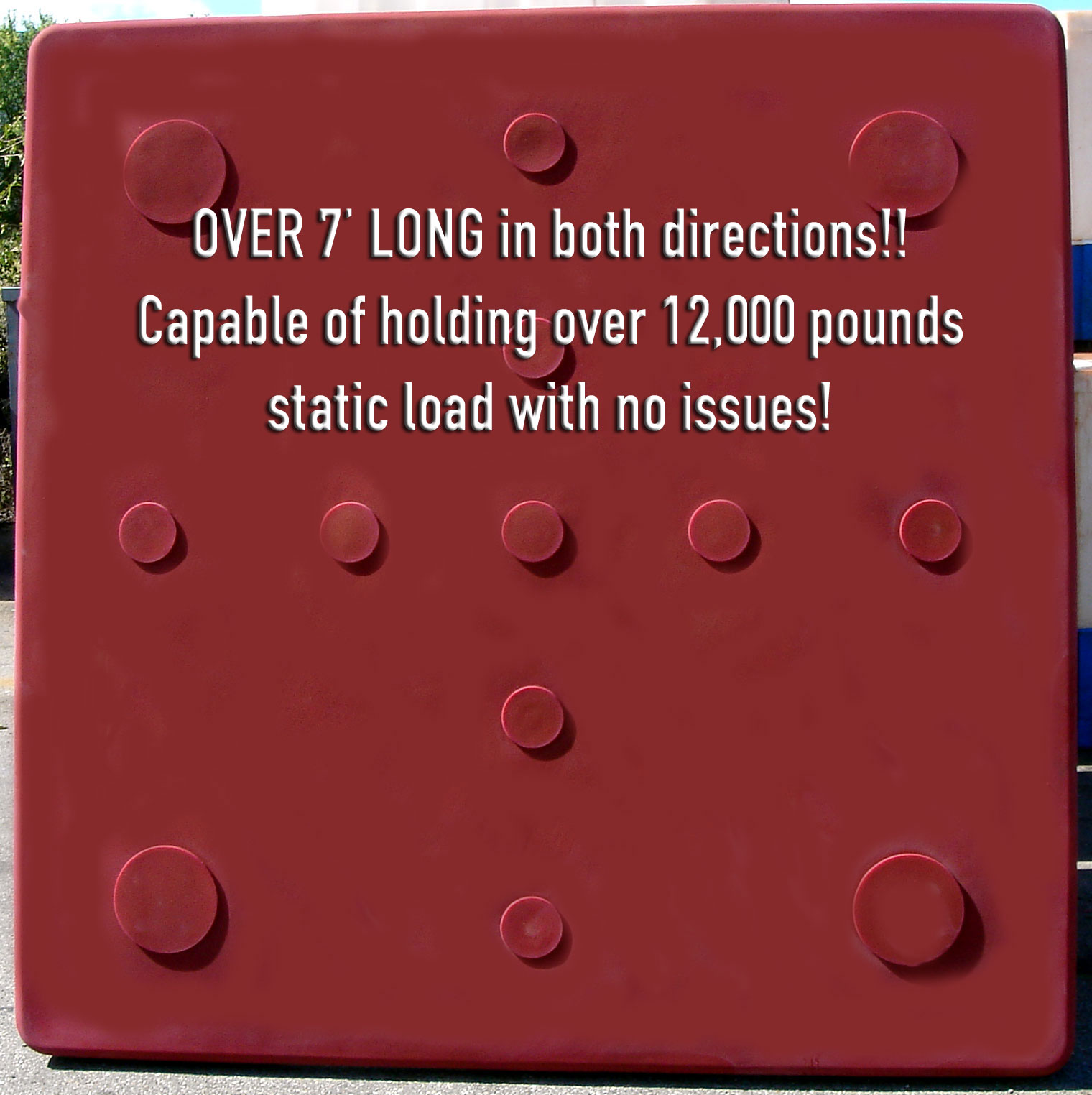

Plastic Pallets typically can incorporate the same features into a plastic pallet as a wooden pallet. Stackable, Rackable, Nestable, Heavy Duty Capacities and more can all be incorporated into the design of a custom plastic pallet. Heavy duty weight capacities, Racking capabilities and so much more is possible to achieve with a custom plastic pallet.

For any Plastic Pallet Inquiries, please Contact Granger Plastics. If the size or features of your plastic pallet are not available, Granger Plastics can build the toolding (molds) and produce the plastic pallet to meet your specifications. However, please keep in mind, tooling and or a mold to rotationally mold these pallets is required.

Plastic Pallet Image Gallery

Plastic Pallet Information

For more information on the Plastic Pallet: Click Below