Mold Shop & Metals Fabrications

Granger Plastics Company elected to expand its operations in 2004 to begin building molds for rotational molding in-house. This allowed Granger to maintain customers' tools in house, eliminating turn around times, added costs and allowed customers tools to remain in production, thus providing products and components necessary for their projects.

Granger's in house rotational mold making and metals fabrication center offers complete metal solutions coupled with internationally recognized rotational molding capabilities all under one roof! The molds & metals shop contained within Granger Plastics has produced some of the leading tools and products from within the rotational molding industry over the course of the last decade. Frequently in the rotational molding industry, a mold for rotational molding will become damaged or start to show the signs of fatigue and stress. This is where an experienced tooling manufacturing or repair is a very valuable asset. Unfortunately for most of the rotomoulding industry, many less capable Rotational Molding Suppliers do not have or offer in-house tooling repairs or have the ability to make modifications, repairs or build tooling in house. Granger Plastics can not only repair tooling as needed, Granger Plastics can modify tooling in-house, even design and building tooling in house! No additional lead times, no additional freight charges shipping molds all over the country! All maintained in house! As an added bonus, if you elect Granger Plastics as your Rotational Moulding supplier of choice to build your tooling and produce your products, Granger Plastics will maintain that tooling free of charge as long as it is being produced at Granger Plastics! Granger continues to go the extra mile where many other molders fall by the wayside.

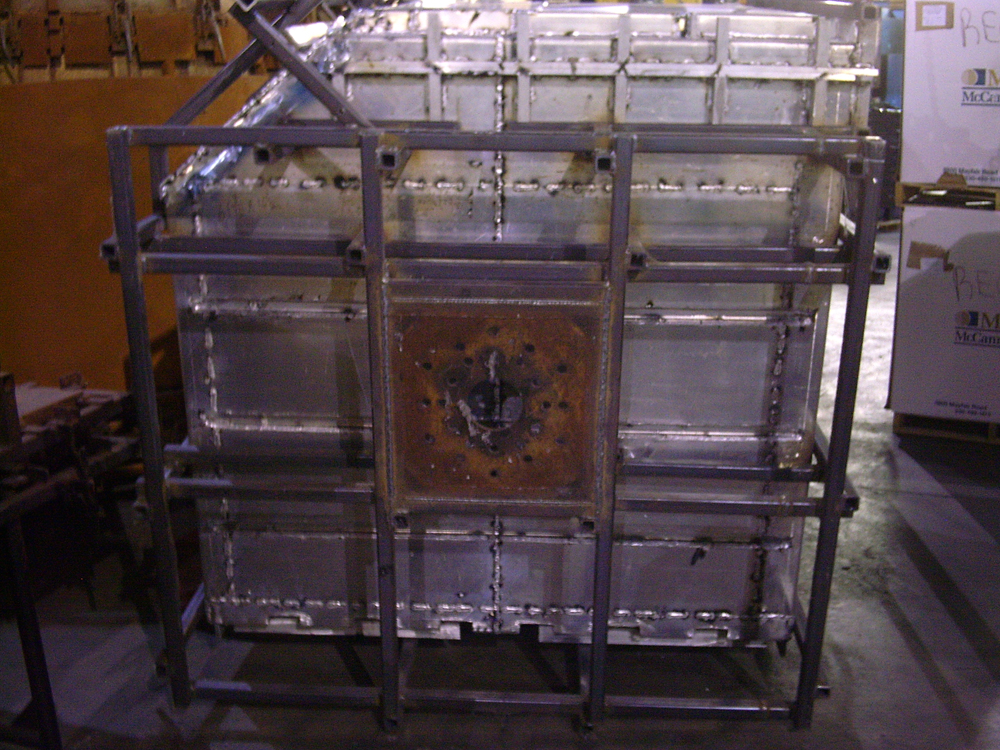

A "small crack" as described by the previous molder; Tooling was received in an inoperable condition! No wonder! |

Look at the POUNDS of snow covering this mold! This mold is recently off a truck, as it is still banded to the skid! Rust? |

Flat? Well, the other molder was telling the customer it looked flat to them! only off 6-8"! |

Granger Plastics can help you design your project, build the tooling or molds for rotational molding, produce the products from your molds or tooling, even trim, assemble, package and/or drop ship them to your customers. Granger Plastics offers complete turn-key solutions to help start or grow your business!

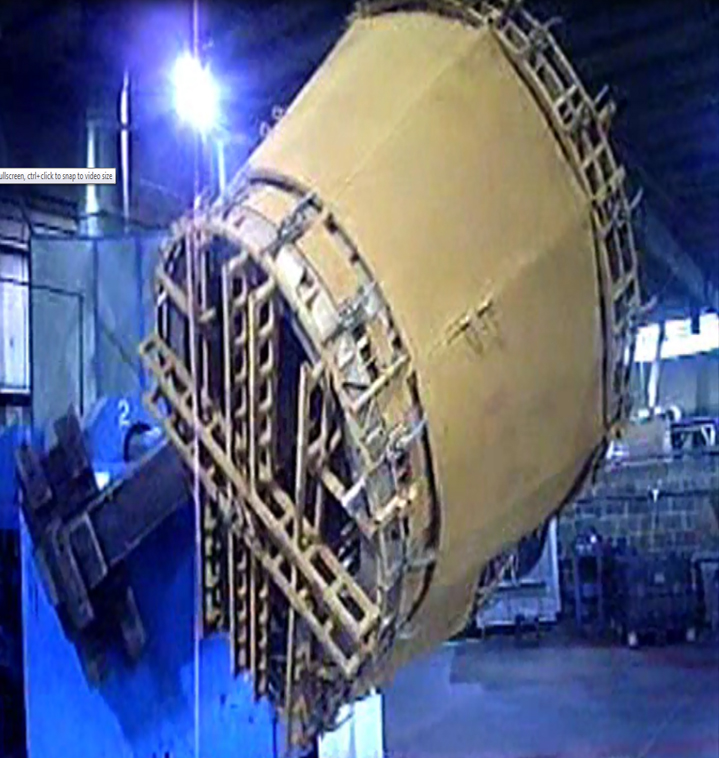

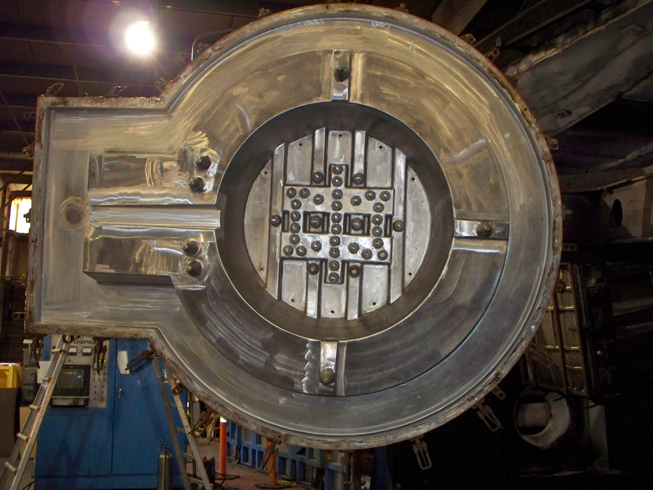

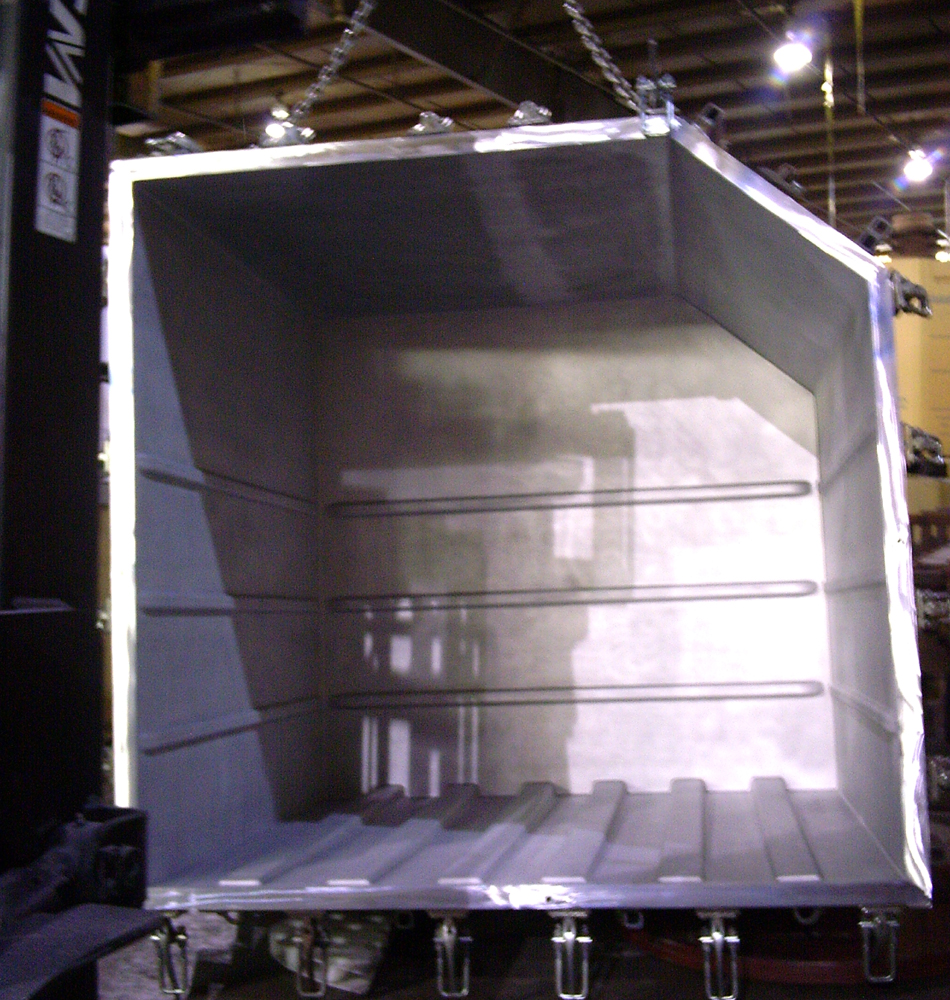

The Granger ISS Tornado Shelter mold is a great example of a high quality mold that required lots of innovation and design to accomplish its goals. A number of trade secrets help manufacture the Granger ISS, but the mold is consistently in production and has undergone a number of moldifications even. It's the heavy duty framework and the heavy duty clamps that make one of the biggest differences in rotational molds being manufactured and parts being produced by Granger Plastics.

The picture above displays the inner plug of the Granger ISS Tornado Shelter mold being pulled. This is probaby the most integral part of the monsterous 3 piece tooling. Also notice the high quality mirror polish finish on the plug of the Tornado Shelter tooling. This allows for a very nice high polished inside surface on the finished product. The tooling for the Granger ISS is probably one of the most intricately designed Rotational Molds in the industry, also while potentially being one of the most expensive. Granger Plastics has performed some pretty astonishing feats inside of its mold shop and metals fabrications departments .

|

|

|

Rotational Mold Tooling Gallery

|

Rotomolding Tooling Links

Granger Plastics Rotomolding Videos

Granger Plastics Rotational Molding Info

For more information on Granger Plastics Rotational Molding: Click Below